BNSF is Building a Stronger & Safer Rail Network

EXPANDING OUR NETWORK AND SERVICE

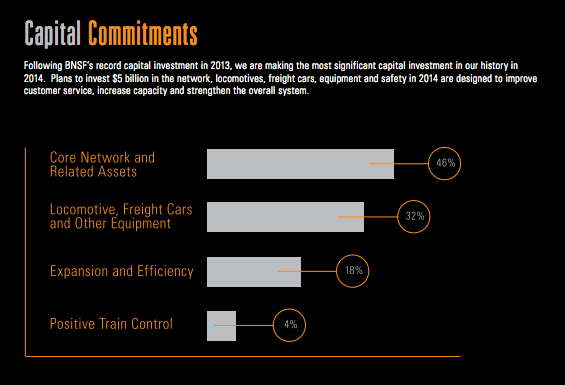

Every year BNSF makes significant capital investments to strengthen and improve our network for customers and the communities we serve. Since 2000, BNSF has invested approximately $42 billion in infrastructure, equipment and technology – including a record $4 billion in 2013.

Leading Intermodal Service

BNSF is an industry leader in moving freight seamlessly between modes – trucks, ships and trains. Today, intermodal truck trailers and containers that primarily carry consumer goods account for approximately half of all BNSF freight volumes. In 2013, domestic intermodal freight led growth for BNSF.

BNSF’s intermodal network connects customers to more major U.S. markets than any other railroad, offering the most flexible intermodal service options in the industry. Last year, we opened our newest intermodal facility, Logistics Park Kansas City, to accommodate growing demand in one of the nation’s most important distribution markets. The new facility represents a $250 million investment with six 8,000-foot tracks and initial capacity to lift 500,000 truck containers per year. Logistics Park Kansas City offers the most comprehensive range of intermodal services on BNSF’s network.

Expanding the Supply Chain

BNSF continues to expand its global reach through the development of industry-leading supply chain solutions to and from U.S. inland markets. For example, where a container with Asian consumer goods shipped to the U.S. might have returned empty, now it carries grain back to Asia after being loaded at one of BNSF’s intermodal facilities like the new Logistics Park Kansas City. With this solution, we’re creating greater efficiency and making the most of every resource.

Supporting Continued Growth

BNSF is playing an important role in helping the U.S. and North America replace overseas crude oil with fuels being produced from the continent’s vast oil reserves. Rail offers oil producers a more flexible transportation option and gives refiners easy access to premium, domestic fuels.

BNSF helped pioneer the modern day crude-by-rail option when the first crude oil unit train left Stanley, N.D. in December 2009. Today, the overwhelming majority of crude oil produced in the Williston Basin is transported by rail. BNSF moved 225 million barrels of crude in 2013 and is ready to meet growing demand in the years ahead.

In 2013 alone, we invested approximately $900 million to improve and expand rail capacity along the Northern Corridor, which spans the northern U.S. between the Pacific Northwest and Chicago, connecting vital regions to Midwest and Eastern markets. This expanded capacity will help improve traffic flow for all freight and passenger trains on those routes.

Renewing the Auto Industry

Two things have changed the face of BNSF’s automotive business and made it one of our fastest-growing segments. First, as the economy strengthened, sales of new cars grew. Second, manufacturers began building new facilities in North America, realizing the benefits of a robust U.S. supply chain and lower transportation costs. Last year, BNSF purchased 1,000 new autorack railcars and other equipment to help us serve the growing domestic automotive industry.

SAFETY

Safety is a fundamental part of our culture and central to our business. BNSF goes above and beyond federal requirements to prevent accidents by ensuring that our network is safe and our people and the communities we serve are prepared to respond to potential incidents.

Safety Training

First in the line of defense against accidents and injuries are our people. BNSF employees share a vision for an injury- and accident-free workplace. Through BNSF’s newest employee safety training initiative, Approaching Others About Safety, we have trained approximately 33,000 team members to be confident and effective when speaking to one another about safety. The program encourages attention to the exposures that result in 97 percent of fatalities and serious injuries. It also highlights opportunities to mitigate risk.

According to the Federal Railroad Administration, 2013 was the second straight year of record safety performance by U.S. freight railroads. Thanks to the diligence of our employees and our effective safety process, we closed 2013 with an injury frequency rate of 1.08 (per 200,000 work hours or 100 employees working full time over a year), a 3 percent decrease over 2012.

Community Emergency Response

In addition to training our people to prevent accidents and injuries, BNSF works closely with communities and emergency response personnel to prepare for emergencies. In 2013, BNSF hazardous materials teams visited 18 states and one Canadian province on our network to train approximately 3,900 public emergency responders. More than 65,000 emergency responders have been trained since 1996 so that people and resources are in place to respond should an accident occur.

Grade Crossings

To continue reducing the risk of incidents at highway-rail crossings, BNSF invests an average of $95 million annually on a combination of grade-crossing maintenance, technology and safety education programs.

The result is one of the industry’s lowest highway-railroad grade-crossing collision rates. Since 1995, the rate of grade-crossing collisions involving BNSF has decreased about 68 percent, from 5.3 per million train miles in 1995 to 1.7 per million train miles in 2013. In addition, BNSF has worked with many communities and landowners to close more than 5,750 grade crossings since 2000.

Network

To keep our network strong and traffic flowing safely, we invest heavily in track repair and replacement of rail, ties and bridges.

BNSF has a longstanding and broad-based risk-reduction program that addresses operational safety across our network for all types of freight. We have implemented new, more restrictive safety and operating practices for transporting crude oil and ethanol to build on that strong foundation, including lower speeds, secure routing of trains, increased track inspections, additional trackside safety warning technology, and increased community emergency response training and planning. We are also working aggressively with the petroleum industry and other tank car owners to ensure new, stronger tank cars take to the rails as soon as possible. These will be built with thicker steel shells, extra protective head shields, thermal insulation and enhanced pressure release valves.

Technology

New technologies that are keeping our network safe:

- BNSF has been a pioneer in the testing and development of positive train control technologies that act as a safety overlay to help reduce the potential for train accidents. BNSF’s PTC system is under construction across 9,400 miles of our network in 21 states.

- BNSF Railway was named to InformationWeek magazine’s list of the top 500 information technology innovators in 2013 for implementation of a mobile, land-based tool that uses lasers to capture thousands of measurements per second of track and related assets for precise monitoring and enhanced safety.

- We are adding more trackside safety technology along our track to detect defects or problems before they can cause a train derailment.

- Automated gates for trucks to enter and exit some of our largest intermodal facilities include a biometric driver identification system and digital cameras to record images of containers, chassis and tractors. The technology helps increase security while improving throughput and reducing truck idling and emissions.