Creating a Better World, Leading With Science

Applying science to provide innovative, cost-effective solutions for our clients

From the first rudimentary coastal wave impact studies more than 50 years ago to the extreme weather effects data-driven modeling of today, Tetra Tech has led with science.

We take fundamental science—like shoreline physics, aquatic pollutant tipping points, and water and waste remediation chemistry—and turn it into actionable, applied solutions for our clients. Tetra Tech’s physical, chemical, biological, social, and data scientists provide the applied science that makes our civic, engineering, and technological solutions work worldwide every day.

At Tetra Tech, science is more than just a body of knowledge or a collection of processes for defining and answering questions. Science is a means for solving problems and a prism through which to see the world and its people—and their potential—in new ways. In this article, we explore how Tetra Tech is Leading with Science by conducting insightful assessments and crafting creative solutions through innovation, data analysis, and sometimes pure ingenuity. These solutions are both efficient and effective, successful and sustainable.

Science and the Art of Assessment

The scientific method of inquiry is fundamental to diagnosing problems and mapping potential paths forward. The projects featured here highlight how our people apply that method to working in partnership with our clients in search of suitable solutions.

Diving deep into wastewater quality: Using science to diagnose a problem

Tetra Tech’s expertise in water and wastewater led a global food and beverage company to our Denver, Colorado, office last year with a simple request: Can you help us figure out what is wrong with our treated wastewater effluent?

The company discharges treated water from one of its production facilities. “Our client was having trouble meeting the discharge requirement for acute whole effluent toxicity testing,” said Kevin Conroy, program manager for industrial water and wastewater treatment at Tetra Tech. “Survival rates for Ceriodaphnia dubia had been an intermittent issue for a number of years and, despite multiple efforts and studies, they had come up empty on a solution. That’s when they contacted us.” Ceriodaphnia dubia, a species of water flea, is used in both acute and chronic toxicity testing.

“In a very short time, Tetra Tech identified the problem, found the root cause, and developed a solution,” said Frank Johns, director of industrial water management at Tetra Tech.

Kevin and Frank began the process by assembling a team of wastewater engineers and reviewing initial facility production information and historical wastewater sampling results from the facility’s treatment plant. After an initial review, they brought in Jerry Diamond, lead scientist at Tetra Tech’s Center for Ecological Sciences.

“Jerry and his staff in Owings Mills, Maryland, are well known and highly regarded for their work in aquatic biology,” Frank said. “We were pretty sure they could shed some light on what was going on.”

With effluent samples in hand, Jerry and his laboratory scientists went to work at Tetra Tech’s Ecological Testing Facility.

“Working with my laboratory director, Marcus Bowersox, and his staff, we designed and conducted a comprehensive toxicity identification evaluation and paired that with the chemical usage and wastewater plant info from Frank and Kevin to collectively identify the cause of the problem,” Jerry said. “The teamwork approach between the wastewater process engineers and the toxicologists was the key to identifying the issue and developing a practical, cost-effective solution.”

“It was magnesium,” Kevin said. “Way too much magnesium for the organisms to survive. That’s what the initial investigation by Marcus and his team told us.”

In this case, the source of the elevated magnesium concentrations was easily identified. Magnesium hydroxide is a common compound for neutralizing pH in wastewater, and the treatment plant had been using more and more of it to maintain proper pH levels in the treated effluent. This raised questions about why usage had increased and the underlying cause of that increase.

“To get to the bottom of the high magnesium hydroxide usage and to develop effective solutions, we needed to do a very deep dive into the facility production operations,” Kevin said. The team determined that changes to production operations to eliminate the high magnesium consumption could not be implemented and that instead, changes to the wastewater treatment process were necessary to make it more robust and reliable.

The team developed and evaluated a range of modifications to the treatment plant’s equalization and pH neutralization systems to take advantage of residual high pH chemical solutions from production equipment cleaning. This not only reduced the pH to acceptable levels, but also reduced overall chemical consumption with an associated reduction in operating costs. They also recommended better equalization and control system strategies to minimize magnesium hydroxide use.

“This all started out as an inquiry based on my past work and relationship at this site, which turned into a $350,000 study and a very happy client,” Kevin added. “And the best part is the conceptual and preliminary engineering work that we did as part of the study was used by the client to develop their specific plans to upgrade their wastewater plant. That contract was awarded a few months ago, and we were the successful bidder.” An initial $1-million project is now underway to fix the basic problem. The next project will be to make additional wastewater system upgrades to further improve overall wastewater operations and decrease long-term compliance risk for the client.

Learn more about how Tetra Tech helped its food and beverage client solve a wastewater effluent toxicity problem.

Making the most of breakfast, lunch, and dinner: Using science to analyze raw data

For researchers Tamara Shulman and Belinda Li in Tetra Tech’s Vancouver, British Columbia, office, science offers a method to measure and probe the global problem of food waste, which amounts to more than 1 billion tons annually worldwide and generates millions of tons of greenhouse gases, according to the United Nations Food and Agriculture Organization. Our teams recently conducted a pair of food waste characterization projects, one for North America’s Commission for Environmental Cooperation (CEC) and the other in partnership with the Natural Resources Defense Council (NRDC).

For the CEC, Tamara led a high-level investigation into the causes of and potential programmatic responses to food waste, featuring interviews with 170 key players in the industry, research and literature reviews, and a three-day stakeholder brainstorming and number-crunching session. In the United States alone, the value of food wasted annually is estimated at $162 billion, with most waste occurring among consumers, restaurants, grocery stores, and institutional food service entities (see sidebar).

The information Tetra Tech collected in these studies will be used to help meet the U.S. Environmental Protection Agency’s 50-percent national reduction goal to be achieved by 2030. Tetra Tech’s work provided an essential diagnostic analysis of the composition of food waste, using existing research and qualitative information to fill knowledge gaps and develop studies that further probed what was happening at the bottom of the bin.

Belinda, who led field research for the NRDC project, discussed how the science of dumpster diving can shed light on why people throw food away. “Our CEC work identified some gaps in what we know about food waste, which helped us design a multipart study to find out more,” Belinda said. “We wanted to collect data from the residential and industrial side of the issue—to know more about why food was being discarded.”

The project engaged selected households in Denver, Nashville, and New York to track what they threw out and why. Participant diaries, which included behavioral information, were supplemented by surveys and targeted bin digs. The research team took samples from participants’ waste containers to verify self-reporting in waste diaries. The team also recruited businesses in the three cities to agree to turn over the contents of their waste bins for examination.

“There are lots of interesting revelations in the waste bin!” Belinda noted. “You can tell when people had too much food and forgot about it in the fridge. Those waste samples were usually pretty spoiled and moldy.”

Turns out you can make scientific inferences about why something was trashed from a clump of fetid kitchen garbage.

This is the first time this type of direct data collection had been done in the United States,” Belinda said. “Linking actual behavior with reported behavior and inferred statistics is extremely important in developing actionable results.”

Tamara said the results of Tetra Tech’s multifaceted research effort already are being used to support the development of new waste reduction policies. “We’ve been integrating our research and data with other information to create innovative solutions for clients interested in waste reduction,” she said. The research helped to characterize existing food waste streams and associated behavior patterns linked to food waste. This type of research can lead to more efficient composting, separation of waste processing for various types of food, and better methods to reduce waste at the source.

Tamara noted that Tetra Tech’s Vancouver office already has put their findings into practice with an in-house waste reduction pilot project. Employees in an experimental group received side-saddle waste containers connected to larger recycling bins beside their desks—and brought materials generated at their desks to centralized zero waste stations—reducing office waste by 85 percent compared to employees in the control group, who had only paper recycling and traditional trash cans emptied nightly by custodians.

Learn how Tetra Tech is using its expertise to help reduce food waste in Canada.

Designing and Implementing a Solution

Assessment analyses help to synthesize clear solutions to complex problems. The projects featured here span the globe and demonstrate the ingenuity and creativity released when Leading with Science.

Getting a GRIP on groundwater replenishment: Using science to turn plans into engineering designs

Tetra Tech is the lead designer for the Groundwater Reliability Improvement Project (GRIP), which is helping protect water supplies for more than 4 million residents through the development of an innovative aquifer injection system in Los Angeles County, California, for the Water Replenishment District of Southern California.

GRIP is part of a larger effort to make this area water independent,” said Kara Buttacavoli, Tetra Tech project engineer. “We’re supporting the construction of a new facility on the San Gabriel River that will take the discharge from an existing wastewater plant and further polish it via reverse osmosis, ultrafiltration, and ultraviolet treatment. After that, the treated water will be piped to a series of injection wells and percolation basins, where it will help to replenish the regional aquifer. We’re talking more than 3 billion gallons of water annually from just the GRIP part of the larger replenishment project, so it’s significant.”

Making this ambitious plan reality in just 24 months is the perfect example of applied science. Working closely with the contractor, Tetra Tech will create a detailed design that will run more than 800 design sheets and have 1,200 components. Our design will be fully digital using 3-D building information modeling, or BIM, design methods, allowing the team to anticipate any design needs and fully integrate the ambitious training, habitat, and public education features into the process.

It’s meant to show people how the recharge system works in miniature,” Kara said. “The district is planning to use it as a demonstration site for school tours and other educational programs. It’s really going to be a showcase for sustainable water management in this part of the state.”

Other facility features include habitat areas for the monarch butterfly, bike paths linked to the existing river trail, and an open lawn space with an amphitheater.

Watch a video about how Tetra Tech is using innovative technology to recharge the groundwater in Southern California.

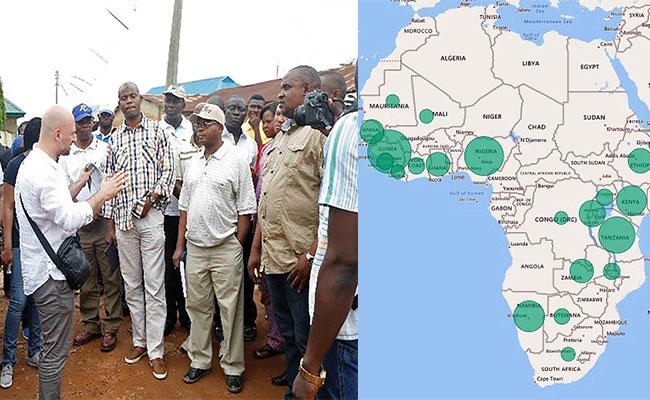

Powering Africa with appropriate technologies: Adapting science to local conditions

Tetra Tech staff often work at the intersection of several scientific disciplines, addressing wide-ranging client objectives through an ever-growing palette of integrated solutions. Half a world away from the United States, Llyr Rowlands and Miguel Franco provide high-level technical and consultation support to Power Africa, a U.S. government-led partnership working to add 60 million new electricity connections and 30,000 megawatts (MW) of new and more cleanly generated power in sub-Saharan Africa by 2030. Tetra Tech’s work with Power Africa includes large regional efforts, utility-scale generation projects, and solutions for the smallest power needs.

In African communities, the switch to electricity can be advanced by some of the most cutting-edge, microscale technologies. Emerging science linked with innovative delivery can provide light in homes, energy for technology, and advancement in industry. A key component to the program is integrating new science in energy generation with an understanding of local resources and needs and long-term sustainability of infrastructure.

“I’m focusing on the off-grid component of Power Africa,” Miguel said. “These are projects under 10 MW and include micro-grid and solar home systems. We’re talking about projects that produce power for a small group of homes or businesses, sometimes just big enough to light a house, charge cell phones, and power a computer. We try to find sustainable solutions to the critical need for electricity on the continent at whatever scale fits the situation.”

This ambitious initiative, supported by more than 140 public and private sector partners, is coordinated by the U.S. Agency for International Development (USAID). Partners include technical and legal experts, private companies, and governments from around the world who are working together to increase access to electricity for the 600 million people in sub-Saharan Africa who currently live with little or no power. Opportunities for addressing their needs include multiscale solar, wind, geothermal, natural gas, and other emerging technologies.

In 2014 USAID chose Tetra Tech to manage many of the technical, environmental, and policy-based aspects of the Power Africa initiative. Llyr, Miguel, and their team support the Power Africa Transactions and Reforms Program (PATRP) by conducting scientific studies of power project plans, technology and system design reviews, electricity grid modeling, hydrological surveys, environmental and social impact assessments, capacity development planning, and business development activities.

“Power Africa has already achieved several thousand megawatts of generation with our support, and there are more than 20,000 MW in the pipeline,” Miguel said. “Some projects are in the planning stages, some are seeking funding, some are under construction, and some are producing power. It’s an exciting time.”

Learn more about Tetra Tech’s support of Power Africa at tetratech.com/PATRP.

Going green in the Motor City: Combining social science with stormwater science

The science of managing urban stormwater—polluted runoff from homes, businesses, parking lots, and streets—is standard practice these days. Hydrology, hydraulics, and the physical, chemical, and biological dimensions of water quality all play important roles in assessing and addressing stormwater challenges.

But working in urban environments requires more than robust qualifications in the scientific and technical aspects of permit compliance and implementing best management practices. Working in the city is about making people’s lives better—and about the experience of living in a city. Combining an understanding of the social fabric of a city with stormwater management know-how can enhance the community. Tetra Tech’s stormwater professionals address water management needs while creating tangible, visible benefits to the community.

Carol Hufnagel, Tetra Tech’s national wet weather practice leader, has seen the once slow and awkward dance between stormwater design and social sciences synchronize over the years. She has witnessed this surprising development in Detroit, Michigan, for example, where Tetra Tech is the program manager for the city’s green infrastructure efforts.

“When you’re working in an urban environment, you’re not just dealing with engineering and technical issues related to water quantity and quality,” Carol said. “You’re doing things that impact the whole fabric of the city.”

Carol points out that stormwater can impact so many things: flooding, property values, vacancy rates, and quality of life. Done right, green infrastructure can help address those challenges and more. A case in point is Tetra Tech’s redesign of Detroit’s Viola Liuzzo Park, which won the Climate Change Business Journal’s Business Achievement Award for Project Merit at the Environmental Industry Summit XV in San Diego in January 2017.

At Viola Liuzzo Park, Tetra Tech incorporated green infrastructure into a park revitalization project, integrating three bioretention areas—sometimes referred to as rain gardens. The bioretention features will treat and infiltrate stormwater from streets and sidewalks while providing landscaping that aligns with the community’s vision for the park.

Carol explained that the confluence of issues that were most important to the Detroit Water and Sewerage Department (DWSD) included combined sewer overflow control, significant flooding that resulted in combined sewage in residents’ basements, a strong interest in neighborhood revitalization and beautification, and economic and public education concerns. Tetra Tech considered these factors in prioritizing potential projects. In addition, DWSD and Tetra Tech collaborated with many partners and conducted a wide range of analyses to gain an understanding of the community’s wants and needs.

“We had tools for analyzing the strength of the neighborhood, building vacancies, property values, past targets for public funding, and public opinion,” Carol said. “We worked with literally dozens of stakeholder groups.” The list included city departments including public works, parks, planning and housing and revitalization; nongovernmental organizations; foundations; neighborhood groups; and the district city council representative.

The team’s collaborative, community-focused approach illustrated how revitalizing parks brings people together. Stakeholders began to see how everything is related—flooding, water quality, air quality, road resurfacing schedules, sewer line work, park development, greenways. They also found that if they communicate with each other, they can coordinate and collaborate on all these issues, address their flooding and stormwater problems, and build stronger communities.

Learn more about the community-oriented solution for Viola Liuzzo Park at tetratech.com/LiuzzoPark.

Designing for performance, building for endurance: Using science to optimize asset management

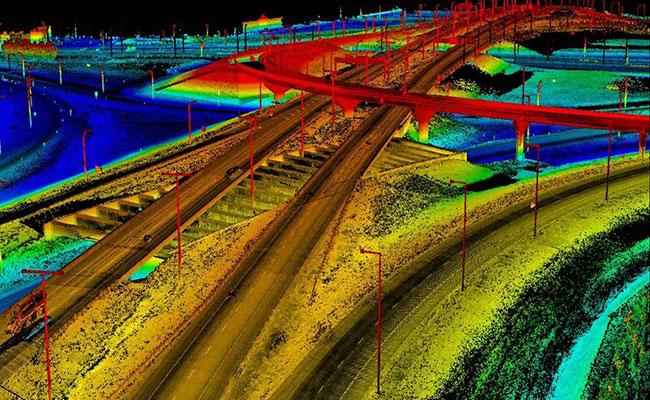

Tetra Tech is the acknowledged leader in the water, waste, and environmental sectors, with No. 1 and top 10 rankings to prove it. Now, a new category of infrastructure is emerging as a potentially significant growth area, driven by designs informed by a whole new array of specialized analytics.

“People have always thought about pavement in a pretty routine way,” notes Bryan Palsat, a pavements engineer in Tetra Tech’s Vancouver, British Columbia, office. “The client tells you what to build and how to build it, and that’s that. There wasn’t much attention paid to long-term operation and maintenance until later. However, we are seeing a whole new approach to road building in both Canada and the United States. No one has the hundreds of billions of dollars needed to repair and replace all of our crumbling roadways and bridges.”

The public-private partnership—PPP or P3—approach has emerged as a favored method of project delivery, Bryan says, and it requires a different mode of thinking about total project costs.

“Under the PPP model, you have the traditional design-build method, but you also have the financing and operations considerations folded in,” he said. “The concessionaire who is operating and maintaining the road suddenly has a lot of interest in how it is designed and constructed, because those two things have a major impact on long-term performance. That is where we come in.”

Bryan noted that Tetra Tech's pavement investigation expertise dates to the 1980s and includes all aspects of road building—engineering, design, materials, analysis, and nondestructive pavement testing. Our team uses a suite of carefully collected assessment information to analyze roadway degradation, getting at the root problem causing the cracking, rutting, and potholes that plague drivers and municipal budgets.

“There are lots of variables—climate, design, materials, construction, repair methods, type of use,” Bryan said. “We do our own testing, to see firsthand how pavement responds to these variables. All that data goes into models we build to forecast future pavement conditions. We’re able to project maintenance and rehabilitation needs based on how the road was designed, built, and operated. That sort of knowledge can save the owner-operator 10–15 percent or more over the long term. When you are considering transportation projects in the hundreds of millions or billions of dollars, those kinds of savings really add up!”

Tetra Tech has leveraged its niche in pavement management for PPP projects in Canada into a broader portfolio that now includes airport runways and partnerships in the United States and beyond.

“Nobody else does what we do,” Bryan said. “We use our experience and analytical expertise to develop performance-based designs that specify not just how to design and construct the roadway pavement, but how it should function over its expected life span.”

“It’s all about using the data to analyze lifecycle costs and identify and define the performance requirements up front,” he added. “We’re working with our clients to support design and construction elements that maximize usefulness and minimize operation, repair, and maintenance costs over the long term to reduce overall expenses. That can save a lot of money, and for our clients, that’s the bottom line.”

Building on our reputation for excellence and innovation

From assessing problems and probing potential paths forward to creating and implementing clear solutions to complex problems, Tetra Tech teams are Leading with Science throughout the project life cycle. Tetra Tech brings together interdisciplinary talent from across our global operations to work together to deliver solutions to our clients. We lead with science every day, applying that broad discipline to developing practical solutions that advance our clients’ projects around the globe.