Crown Holdings 2022 Sustainability Report: Progress Toward Our Twentyby30™ Goals

Originally published in Crown Holding's 2022 Corporate Responsibility Report

While progress toward all our Twentyby30™ goals is a priority, there are several areas of heightened focus where we feel we can accelerate the impact we can make for our business, our customers and our communities.

Acting on Climate Change

Slowing climate change requires swift action, innovative thinking and collaboration. As a global manufacturer, we have a key role to play in minimizing and mitigating climate risks and are committed to working internally and with external partners to reduce the global carbon footprint of our business activities. We are doing this in several ways:

We have defined science-based emission reduction targets, approved by the SBTi, confirming that our goals are in alignment with the Paris Agreement to limit the global temperature increase to well below 1.5 degrees Celsius. This commitment continues to push us as a Company and motivates each of our individual employees to be even more ambitious in reducing our environmental impacts and accelerating progress against our stated GHG emissions goals. The efforts that come out of our Twentyby30™ Best Practices program and Chairman’s Sustainability Awards are just a few examples of the ways we are minimizing energy use and emissions.

We committed to Climate Group’s RE100 and joined The Climate Pledge, reinforcing our commitments to prioritize climate change by using renewable energy sources and supporting methods to reduce our carbon footprint. Each year, we continue to increase our reliance on wind and solar power across our operations. For example, all greenfield plants will include solar panel installations. In fact, our Mesquite, Nevada (U.S.) plant will be able to run on close to 100% solar electricity on sunny days when fully operational.

We are also addressing emissions reduction by taking steps to unlock more value from existing resources. For example, our multi-year beverage can light-weighting initiative, which resulted in a substantial 6.44% global average reduction in our standard 12oz. or 330ml can weight, reduces the need for virgin metal and enhances the continual re-use of aluminum. By using less material in each package, we decrease material usage and our overall energy consumption and the associated GHG emissions. Notwithstanding their lighter weight, our beverage cans retain the safety and durability standards our customers and consumers have come to expect.

“Each year, we continue to increase our reliance on wind and solar power across our operations”

Coming Full Circle

We are committed to supporting impactful recycling practices, educational efforts and policies to boost global recycling in line with the Optimum Circularity pillar of our Twentyby30™ program. This takes shape in many ways:

Setting Ambitious Recycling Rates Targets

Aluminum cans are the only beverage packaging format currently capable of being consumed, recycled and transformed into a new product on the shelf within a 60-day turnaround time. This is a powerful attribute for the material, but greater effort needs to be invested to recapture and reuse as much aluminum as possible. To support this mission, in 2022, we worked with industry partners to establish ambitious new global recycling rates goals for the format.

Designed to be completed by 2030, the targets focus on the inherent recyclability of metal and commitments to foster an ever more responsible industry. The targets are connected to the regions where Crown maintains operations and include reaching a 70% target in the U.S. and an 80% target in the European, Middle Eastern and African countries in which we operate. Our goals include maintaining rates of greater than 90% and 97% in Mexico and Brazil respectively. Countrywide goals for Cambodia, Thailand and Vietnam, the three major Asia Pacific markets in which we operate, will be established by 2025, once current recycling rates are further researched, work that is currently underway.

Advocating for Clearer Recycled Content Standards

To facilitate actionable progress toward the aluminum industry’s sustainability goals, we were a lead organizer in the industry’s first Global Aluminium Can Sustainability Summit in 2022. Among the topics discussed at the event was the need for stronger recycled content definitions, including setting an industry standard to create an even playing field for manufacturers and brands. Getting there will require defining what constitutes recycled content, deciding how to measure recycled content levels and educating consumers—steps that will ultimately help us meet our ambitious Twentyby30™ goal of achieving a global recycled content average of 80% by 2030.

To date, Crown has participated in a task force comprised of other engaged industry members working toward a standard that outlines how to measure recycled content in the aluminum value chain. This work should culminate in 2023 with a published standard.

Assessing Circularity Across our Operations

After joining the Ellen Macarthur Foundation’s Network as a Member in 2021, we completed our first Circulytics survey in 2022. This Circular Economy performance measurement tool has enabled us to assess our full operations, extending beyond materials flow alone. We are currently evaluating the opportunities we have to enhance our circularity performance across our business and will be incorporating them into our processes and plans in the months and years ahead.

Making What’s Old New Again

Our effort to increase the recycled content levels and circularity of our products extends to our transit packaging portfolio, including tier sheets, slip sheets, top frames and plastic strapping.

For example, the plastic tier sheets manufactured in our Eden, North Carolina (U.S.) facility contain an average of 18.7% recycled content. Made from a blend of two polypropylenes in multiple sizes and thicknesses to suit different product applications, the durable sheets are washable and reusable up to 100 times. At the end of their useful life, the sheets can be recycled through our Recapture Program. This buyback program allows customers to reduce waste and disposal costs and helps us decrease dependency on new raw material. We regrind the returned sheets and use the recycled polymer in the manufacture of new products. In 2022, the Eden facility recycled 4.7 million pounds of tier sheets, an increase of 71% over 2021. Crown facilities were a significant contributor to the total volume collected, returning 1.4 million pounds of tier sheets. The tier sheets are currently used in 19 of our beverage, food and aerosol can plants in the U.S., Canada, Mexico and Spain.

To supplement the material received through the Recapture Program, several of our Transit Packaging Division’s plants proactively utilize curbside recycling as another resource. Bales of dog food bags, toothpaste tubes and other plastic goods are washed, reground and transformed into new products. In our Eden, North Carolina (U.S.) recycling plant, the emphasis is on collecting high-density polyethylene (HDPE) to produce new flake that is used to manufacture slip sheets in our Kankakee, Illinois (U.S.) facility. In 2021, 60% of the material used to manufacture slip sheets came from curbside recycled materials. In our Florence, Kentucky (U.S.) plant, PET plastic that is collected curbside undergoes a similar process, with recycled material being used to make new plastic strapping.

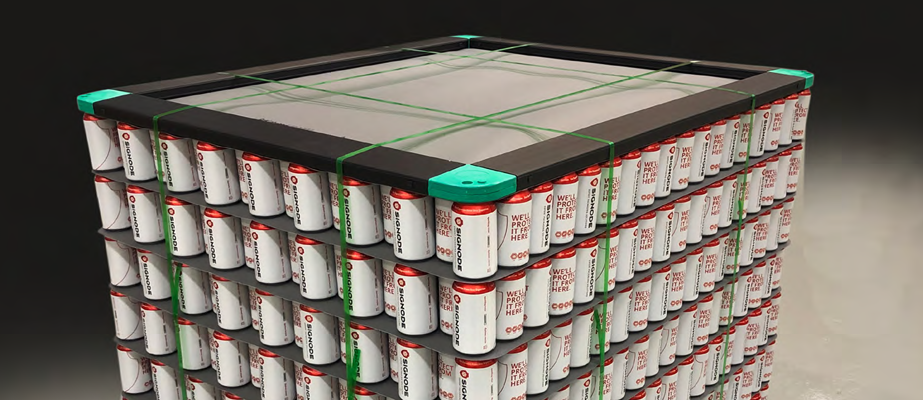

Work is also underway to better reutilize the polycarbonate and nylon used in our PTC top frames, which create a rigid, interlocking framework to unitize and secure bulk palletized loads. Members of our Eden facility are examining ways to increase access to these materials and optimize the process to reuse it to make new products.

To learn more about Crown Holding’s commitment to corporate responsibility, visit our sustainability webpage.

For full details about Crown Holding's 2022 Sustainability Report, visit here.