Ecocentricity Guest Blog: What About Those EV Batteries?

By: Maurice Carter

Ecocentricity Guest Blog: What About Those EV Batteries?

Not long ago, nickel was a coin, cobalt was a paint color, and lithium was a drug used to treat certain mood disorders. You might have heard of lithium-ion batteries, but they weren't something sold from a rack in the checkout line at your drug store. Even if there was one inside your cellphone, you couldn't get inside to touch it.

Electric vehicles (EVs) changed that. Or, rather, America's late-to-the-party-gotta-catch-up embrace of EVs coupled with global supply chain issues have made batteries fodder for headlines like these:

- CNBC: How a global nickel shortage could disrupt the electric vehicle industry

- Axios: Ukraine crisis clouds global EV rollout

- CNN: How a battery shortage could threaten US national security

- New York Times: The Lithium Gold Rush: Inside the Race to Power Electric Vehicles

Locally, public reaction for and against Rivian's planned assembly plant near Rutledge, Georgia has placed an even sharper edge on concerns raised by global events like the war in Ukraine.

We've gone from no one paying attention to the electric vehicle battery supply chain to everyone freaking out about it. So, is the hysteria warranted Concern, yes. Hysteria, no. It's true, the current supply chain is heavily dependent on foreign sources for battery materials, and EV batteries are predominantly manufactured outside the US. A New York Times story last year reported "If current trends continue, China is projected to have 140 [battery] gigafactories by 2030, while Europe will have 17 and the United States, just 10." That's a problem. It's also a good reason to be excited about the massive SK Battery America plant in Commerce, Georgia.

Are Batteries the New Oil?

Oil companies and other fossil fuel interests have waged a well-documented misinformation campaign against clean energy for years. So even those with good intentions sometimes mix fact with fiction. The CNN story above includes the assertion: "Electric cars need batteries the same way combustion cars need fuel -- and the metal in those batteries can be just as precious and hard to get as gas."

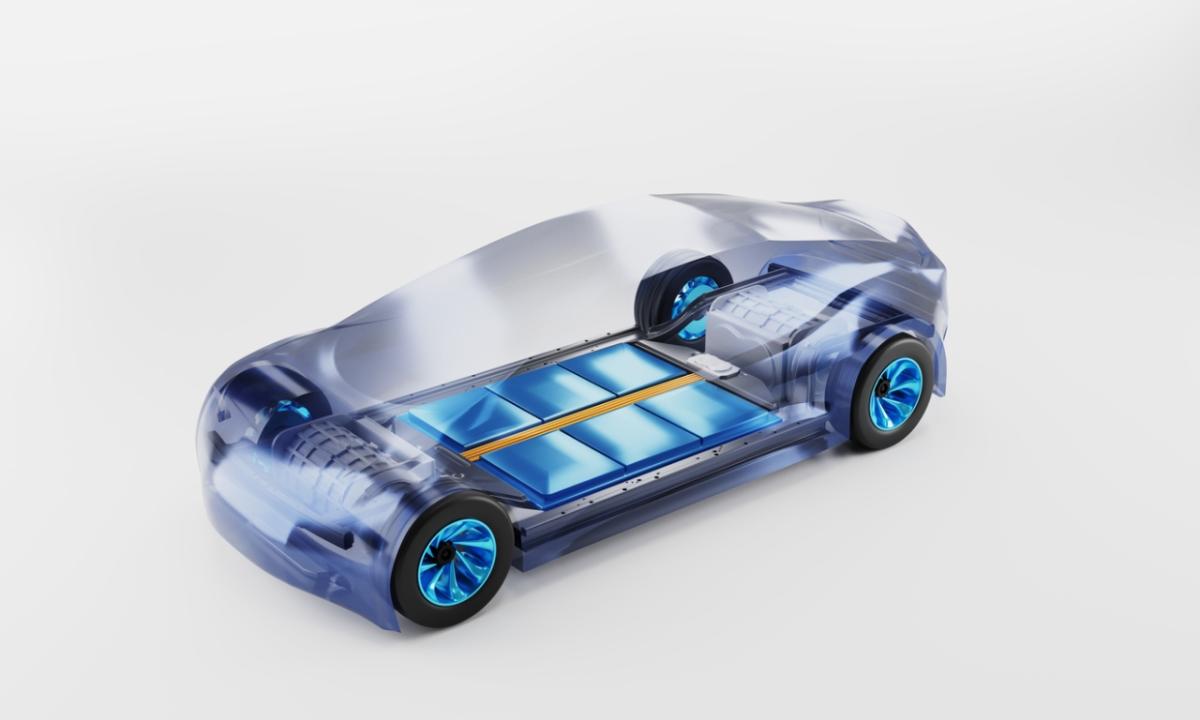

Do EV batteries contain hard to get materials? Sure. Do "electric cars need batteries the same way combustion cars need fuel"? Absolutely not. Most new EVs come with a 10-year warranty on the battery pack. A gallon of gasoline burns in ~30 minutes in a moving internal combustion engine (ICE) vehicle. An EV battery pack is analogous to the fuel tank in an ICE vehicle. Electricity is the gasoline. Oil refined to make gasoline is a finite resource. When generated from renewable sources (wind, solar, or geothermal), electricity is infinite.

Naysayers will note electricity to charge EVs comes from power plants that emit greenhouse gases, but nuclear and renewables have greatly reduced those emissions. The US Department of Energy has a nifty interactive tool to compare tailpipe emissions for gasoline, hybrid, plug-in hybrid, and all-electric vehicles where you live, based on the fuel mix for the electric grid in your state. And the mix is only getting cleaner as utilities shutter coal plants and add more wind and solar.

Challenges Ahead, But Also Solutions

The problem with EVs is not the inherent design or power source. The challenges arise from the unprecedented rate at which we must scale production. President Biden set the ambitious goal of having 50% of all vehicles purchased in the US by 2030 be electric. For their part, US automakers are running well ahead of the White House with their own commitments to an all-electric future. Scaling so rapidly will require a lot of batteries, put a strain on existing supply chains, and require strategic thinking to minimize dependence on foreign sources of materials. Thankfully, solutions are taking shape on many fronts:

- We need responsible domestic mining for nickel, cobalt, lithium, and other materials. According to news reports, President Biden is likely to invoke the Defense Production Act to increase US production of battery materials.

- The very best place to mine materials is from existing spent batteries and scrap from the battery manufacturing process. Ascend Elements, which will open North America's largest lithium-ion battery recycling facility in Covington this summer, is one of many companies building new recycling facilities and pioneering more efficient, lower cost recycling processes. (To learn more, join us on April 22 for our virtual conversation with Ascend Elements VP Roger Lin.)

- While one set of researchers/investors scales up the recycling process, another group is working on new battery technologies that charge faster, last longer, are easier to recycle, and ultimately require less (or no) rare materials. They announce new breakthroughs almost weekly. Because I'm fascinated by the technology advancements in a field so critical to our future, I recently joined a group from the battery industry called Battery Brunch, which started a few years ago as a monthly gathering of San Francisco Bay Area battery engineers and has grown into a global collaboration of more than 20,000 energy storage professionals. The monthly Saturday "brunch" is virtual now, but it draws participants from all over the world. The technical aspects go right over my head, but the intellect, commitment to sustainability, and collaborative spirit are very reassuring.

Beyond advancements in the battery supply chain itself, there are other areas where we focus is critical to making it through the current crunch.

Efficiency Still Matters; Rightsizing Is Critical

Many EVs offer options for a larger or smaller battery. The bigger the battery, the longer the vehicle's range (the maximum distance it can travel between charges). But bigger isn't always better if the resources in that battery are finite and the supply chain is already strained. Remember: electricity is an infinite resource, but nickel, cobalt, lithium, etc. are not.

EVs are still new (especially in America). Our biggest enemy is "range anxiety" -- the fear I will be stranded when I run out of electricity and can't find a charging station. Our first instinct is to opt for the largest battery we can buy for the vehicle we've selected. But that's a mistake. I drive less than 100 miles most weeks, while a range of at least 230 miles is fairly commonplace on most newer EV models. When I buy a battery larger than my driving pattern requires -- solely for peace of mind -- I consume precious materials that could have been used to build another battery for someone else.

A related issue is buying a vehicle larger than what I need just because it's electric. I've never owned a a large work truck, but the Ford F-150 Lightning, the Chevrolet Silverado Electric, or a Rivian R1T all look pretty enticing. And, why not? I don't really need a truck, but they're so packed with features. And, after all, it's electric! So what's the harm? Here again, though, a bigger vehicle needs a bigger battery to achieve similar range and acceleration to smaller vehicles. And bigger battery means more precious materials used. So, I'll leave those trucks to the people who truly need them (which is apparently a lot, given the three-year backlog in reservations for the F-150 Lightning). And don't even get me started on the all-electric GMC Hummer!

When you shop for an EV or a plug-in hybrid (PHEV), you'll see the EPA estimate for range on the window sticker or in the specs on the manufacturer website. But, you'll also see MPG-e, which is the "miles per gallon equivalent" for comparison of that vehicle's fuel efficiency to what you would find in gasoline vehicle. Higher is better, and it's not uncommon to see vehicles with an MPG-e rating over 100. (You'll also sometimes see the vehicle's efficiency rating expressed as "watt-hours per mile," in which case lower is better.) But regardless of how you think about it, fuel efficiency matters even in the electric world.

Plug In and Chill

The root cause of range anxiety is the lack -- or presumed lack -- of charging stations. At the dawn of the automobile age, there weren't any gas stations either. But we worked through that to the point today we have a gas station on at least one corner of nearly every intersection in a populated area.

Part of the issue is, again, we overestimate how much range (and thus charging) we need. According to the US Department of Transportation Federal Highway Administration, the average American drives 39 miles/day. That's less than 300/week, meaning the average driver would seldom need to charge more than once a week. And most could accomplish that at home, overnight, using either 120V (Level 1) or a 240v (Level 2) charger.

But some of us drive many more miles each day, and most of us take road trips.So public charging stations matter. And, thankfully those are becoming more commonplace every day, aided by a strong push from the public and private sector:

- The Bipartisan Infrastructure Law passed by congress and signed by President Biden in November allocates $5B to expanding EV charging infrastructure along designated corridors (mostly interstates).

- Utility companies have programs to assist companies with technical aspects and infrastructure costs to install EV charging for employees and customers -- such as the Make Ready Program from Georgia Power.

- Local governments like the City of Covington are also making free public charging stations available.

Making charging easier and faster at home, at work, around town, and on the highway reduces range anxiety. So, do DC Fast Chargers that can add 100 miles or more of range in around 30 minutes of charge time. All of this makes us more comfortable leaving home with less range, and it keeps us from wasting precious materials in oversized batteries for our vehicles.

Each of these focus areas matters. We should recognize and account for the challenges that come with scaling up electric vehicles in the US and around the world. But, when we tackle these challenges holistically, we'll find a cleaner, brighter future on the road ahead. Hysteria is never the answer.

Maurice Carter is the Marketing and Communications Director for Sustainable Newton, a grassroots, community-based nonprofit organization founded by like-minded residents of Newton County, Georgia. Sustainable Newton drives solution-oriented local responses to the global issues of climate change and sustainability by building awareness with, engaging, and enabling fellow citizens, businesses and local governments to take positive, meaningful steps.

Ecocentricity is available weekly via email subscription. Click here to subscribe.

Ecocentricity Blog: Beer that Recycles its Carbon Dioxide

Ecocentricity Blog - The War in Ukraine: An Environmental Perspective

Ecocentricity Blog: Climate Town