How Steam Conservation in Food Manufacturing Facilities Provides a Win for the Bottom Line and the Planet

Making your food manufacturing facility’s systems more efficient provides significant advantages—and this doesn’t require a large investment of time or money when you leverage steam conservation.

Food and beverage manufacturing is inherently water and energy intensive, but your operations may be using more of these resources than necessary, meaning that you’re also spending more money than you should. Fortunately, you can reduce your energy costs and cut down on your water use by harnessing the steam your existing systems already produce.

Expensive to generate, and easy to waste, steam is often overlooked, but recovering and reusing it can unlock significant opportunities in your facility. This is called steam conservation, which is the general practice of minimizing steam loss and optimizing the efficient use of steam to reduce energy, total operation costs and environmental impacts.

Enacting steam conservation starts with a thorough review of your system to identify areas for improvement—especially if there are false economies in one area that lead to loss in another. This type of inspection should be a routine task, and we provide a roadmap for this practice to guide your maintenance personnel.

Once you’ve determined where your steam losses are occurring, you can enact simple changes to capture condensate and put it to better use. The potential outcomes for this investment of time and money include lower costs for utilities because your system uses less energy and water. It can also cut down on maintenance costs when equipment is running optimally. And reducing your resource draw is also a more sustainable approach to food manufacturing, which benefits the planet and attracts environmentally-conscious consumers and talent to business. That’s another potential boost to your bottom line.

Here we explore how to identify and make improvements to existing systems that will help you achieve these goals.

Evaluating your current system

The first step to enacting steam conservation and recovery is to examine your current equipment and systems to find the points where steam (and potential energy) is being lost. Make sure you’re also reviewing processes and personnel. You’ll unlock surprising saving potential by evaluating every part of your food manufacturing process, including the people involved.

Go into this with an open mind about what you might find. Too often, we’ve seen facility owners take a ‘shotgun’ approach, where they jump to a presumed root cause for a given issue and implement a solution. But in that process, they haven’t correctly identified the problem, so the ‘fix’ actually doesn’t work as intended, and it may cause another problem altogether.

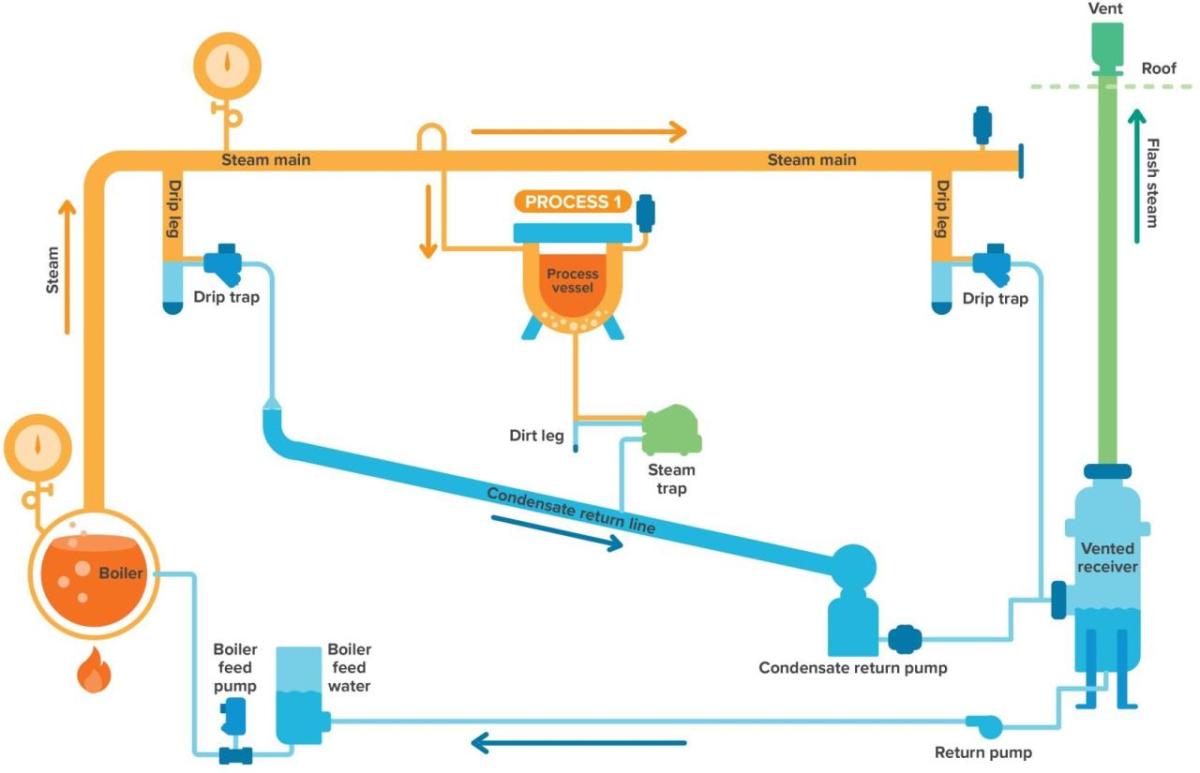

Working from steam users back to the boiler plant can help you understand the overall system and avoid making assumptions about areas for improvement. Perform a physical inspection of the system looking for abnormal operation, damaged equipment, modified system set points, physical losses, and also compare the as-built states to the P&IDs.

A physical inspection of the steam and steam condensate systems should be a routine task for the facility maintenance personnel. While performing an exterior visual inspection of the system and operation, you might find leaking gaskets, leaking valve stem packing seals, stuck open traps, piping integrity issues, abnormal boiler operation, left-open drain points, chemical treatment deficiencies and incorrect system modifications. All of these issues create potential waste.

A full steam survey of a facility should include an assessment of the following:

- Steam and steam condensate system P&IDs

- Steam system mass and energy balance

- Equipment sizing data from the manufacturer

- Operating setpoints of all equipment

- Chemical treatment

- Strainer and culinary filter maintenance records

- Boiler operation, maintenance and inspection records

Finally, the system engineering design review and visual inspection should also look at the application design, appropriate use of steam equipment and piping system design.

Typical loss points in steam and steam condensate include the following:

- Flash steam waste

- Incorrect operation or inefficient operation

- Improper boiler treatment

- Faulty traps and vents resulting in steam passthrough

- Improper condensate return system design

- “Once through steam” where condensate is sent to the drain instead of being returned

- Atmospheric leaks

Older food facilities that have been through a multitude of expansions, facility retrofits and line expansions present unique challenges in system surveys. Sometimes the engineering design isn’t available for the overall system or isn’t current. It’s worthwhile to maintain the system mass and energy balance and system drawings to reflect the existing state of the facility.

Finally, obvious problems such as leaks or failed components don’t require in-depth evaluations. Add these to a preventative maintenance schedule and address them immediately.

Implementing steam conservation and additional improvements

Once you’ve assessed your existing system for inefficiencies, you can turn your focus to proactive improvements at those typical loss points.

Generation

Generating steam requires significant inputs of water and energy to heat said water. As such, it can be a key area for potential losses, but also provide a significant opportunity for savings.

Start by reviewing the mechanical integrity of the boiler system’s equipment. Regular inspections and maintenance are a must to ensure optimal performance and to identify equipment that needs to be updated. Also look for equipment that was installed incorrectly, is worn, or has become inefficient over time. This should be performed routinely, so make sure it’s a part of your preventative maintenance schedule and budget.

Another way to improve energy efficiency is heat recovery of both flash steam and the heat lost via the exhaust stack. This is an easy win; the flash steam recovered from boiler blowdown can be used for nearby lower pressure steam users. Additionally, heat that would normally be exhausted can be applied to generate more steam.

Water composition

Water composition presents another opportunity for optimization; when your water is sufficiently treated and balanced, deposits and pitting are less likely to form in your boilers. Thus, the boilers run more efficiently and need less maintenance. You can identify areas of suboptimal water composition—and thus opportunities to improve efficiency—by adding smart metering to individual lines or a single area of production. Additionally, consider upgrading older chemical metering systems for continuous system monitoring.

Appropriate water composition also decreases the need for extended boiler blowdown and reduces fresh makeup water requirements to maintain balance, both of which draw additional energy for start-up and heating fresh water. Finally, there may be an opportunity to recover heat from the blowdown and use it to preheat incoming water.

Distribution

The next step is to conduct a thorough review of all piping from generation to the equipment. Dialing in the right pipe sizing, length, and routing can make your systems more efficient. Especially if you have an older facility that has undergone modifications and organic growth over several years, you’ll likely find inefficient routing that can be updated and improved. If the originally installed piping is no longer sufficiently sized or routed after the facility has been changed, it can inhibit the flow of steam, causing pressure drops and energy losses throughout the system.

You can also find opportunities for improvement at connections between piping and equipment. Because these are often located in difficult-to-reach and hidden areas, you may not readily notice issues. However, fixing broken valves, leaking gaskets, and damaged insulation can have drastic impacts on efficiency. With a greenfield project, we advocate for a more proactive approach: design piping networks so that they can be ‘walked’ regularly, making inspection is easy and allowing you to identify and address problems quickly.

Optimize system functioning

Look beyond the component parts. You may be surprised to find that your existing system is using more energy or water than it needs to. This is low hanging fruit for improving efficiency and sustainability while reducing utility costs.

Make sure your pressure is right-sized to meet system needs without exceeding requirements. We see systems using the default settings for steam delivery to equipment, which can expend more energy than necessary. Instead, assess your true needs and determine the optimal point for your operations. Again, you may have to make a small capital investment in monitoring systems, but this will ensure your system is generating the right amount of steam.

Users

Review the sizing of users (equipment) in your system to ensure they are operating within optimal parameters. Although equipment might have been set properly when it was installed, these settings can drift and change with time—and it’s not just about the proper steam delivery to the equipment. A regular audit of system performance allows you to make adjustments, save energy, and drive efficiency in your facility with little added cost.

Keep in mind that this review is not just limited to equipment. You can also improve steam specialties like valves, regulators, steam traps, and condensate return equipment (or lack of) to achieve greater efficiency.

Operations staff

Safety is the top priority for boiler operators’ training, but you should also brief them on efficiency measures. Ensuring that operators have on-site training to maintain and optimize equipment functionality will pay off in the long run. Similarly, maintenance staff know how to keep equipment operational but that doesn’t always result in efficient operation. Ensure training includes staff who repair and operate steam users.

Also, note if your jurisdiction requires that certain equipment such as steam turbines should be operated under a different license than the boilers and make sure those operators are also trained in the basics of the rest of the boiler system.

Operations in action

When process staff is tasked with operating steam users, their primary focus can be to keep the process functional, using supporting utilities to make their equipment function. If they aren’t given an understanding of the functionality of the utility systems, it can create inefficiencies, as our team discovered recently:

During an equipment startup visit at a large food production facility, we noticed that condensate return line from a thermal processor was incorrectly installed. During the inspection, the team added the corrective action to the log but the process operator needed an immediate solution to keep the production line and filler operational. The client planned to implement the fix as soon as production was down for the day, so we added a temporary drain line to allow the condensate to drain from the system.

When we returned two weeks later, the valve was still open, and nothing was fixed. In the operator’s view, the problem was solved; however, the system was draining significant amounts of condensate. That should never be considered a normal practice.

Process staff needs training on how to best operate utilities, which includes an understanding of the impact they have on a plant’s efficiency and sustainability.

Advice for engineers

Ideally, in-house engineers should adopt a continuous improvement model as opposed to creating a series of one-off projects. This allows for planned, cumulative improvements that will have greater impact. Regular reviews and long-term planning and execution are the name of the game.

While this is ideal, the real world doesn’t always afford this approach. If leadership doesn’t support sustainability goals, present a case of capital cost versus operating cost and the expected payback period. Incorporating upgrades as part of system expansions or routine maintenance can make the case more palatable.

Quality instrumentation is key to making a business case for capital and regular resource investments to improve efficiencies. For example, boiler water treatment is often a low-cost addition to a system and can be used to gather information to support your plans. Additional instrumentation such as flow meters at high consumption users or pressure transducers at key locations instead of gauges can provide a more consistent view to how the system is operating.

Also, keep in mind the costs associated with the waste that occurs when you don’t implement steam conservation, such as the increased requirements for direct makeup water. Always build in the savings from efficiencies along with capital investment needs as part of your payback calculations.

The team of mechanical and process engineers at CRB have extensive experience in steam generation, distribution and condensate return system design. In addition to new system design, we offer consulting services for existing system evaluations to determine operational inefficiencies and provide reports detailing recommended improvements. Contact us to discuss your needs today.

Looking to improve your system efficiency and improve your bottom line? Our Steam System Assessment Tool can help you prepare a checklist to identify areas for improvement. Download here!