Learn More About How Sappi Reduces Water Consumption

The following offers a view of our annual performance in important areas of environmental and social responsibility. We monitor key metrics for fiber, emissions, energy usage and the impact of our operations on air, water and solid waste. We use this data to set improvement goals for our operations and interactions with key stakeholders.

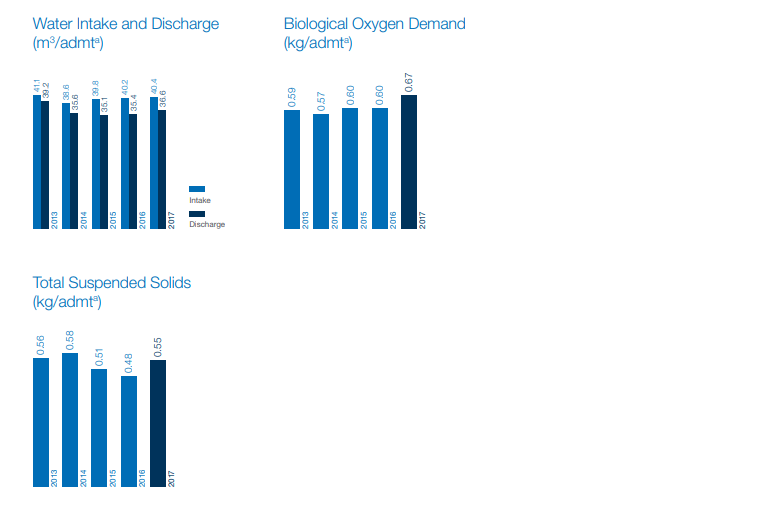

All pulp and paper mills in North America use and treat water in accordance with comprehensive environmental permits. We saw a slight increase in the water quality metrics —biological oxygen demand (BOD) and total suspended solids (TSS)— primarily due to hindered performance of the waste treatment plant at Somerset.

Our North American mills draw water from surface sources (rivers and lakes) and return treated water to the same primary sources. After on-site primary clarifi cation (solids removal) at Cloquet, we send water to a publicly owned treatment facility, where it is treated further and then returned to Lake Superior. Our total water consumption is low because we return a high percentage of the water we use. Water that is “consumed” in our operations is primarily water lost to the environment due to evaporation in the paper drying process and a small amount of moisture contained in our finished products.

Note: We discovered a historic calculation error affecting our reported water use data at one of the mills, which in turn affected the company-level water quality performance indicators previously reported. Data for the five-year trends have been corrected and our total process water use is consistent with prior years.

Read more from Sappi North America's 2017 Sustainability Report here: http://bit.ly/Sappi-SR17