O-I Glass Announces New Ambitious 2030 Sustainability Goals

Glass is already the most sustainable packaging material. Now, we’re taking bold steps to further support its circularity and decarbonization by elevating our 2030 sustainability goals.

“2025 is going to be a milestone year for O-I in sustainability,” said Chief Administrative and Sustainability Officer Randy Burns at O-I’s Investor Day on March 14, 2025. “This year, we are going to hit many of our sustainability goals that we initially set for 2030. Today, we will unveil a new set of even more ambitious sustainability goals.”

This accomplishment marks a pivotal moment for the company. Even as O-I focuses on radically reducing enterprise costs, we’re raising the bar with updated sustainability targets for 2030, with 2019 as the baseline year.

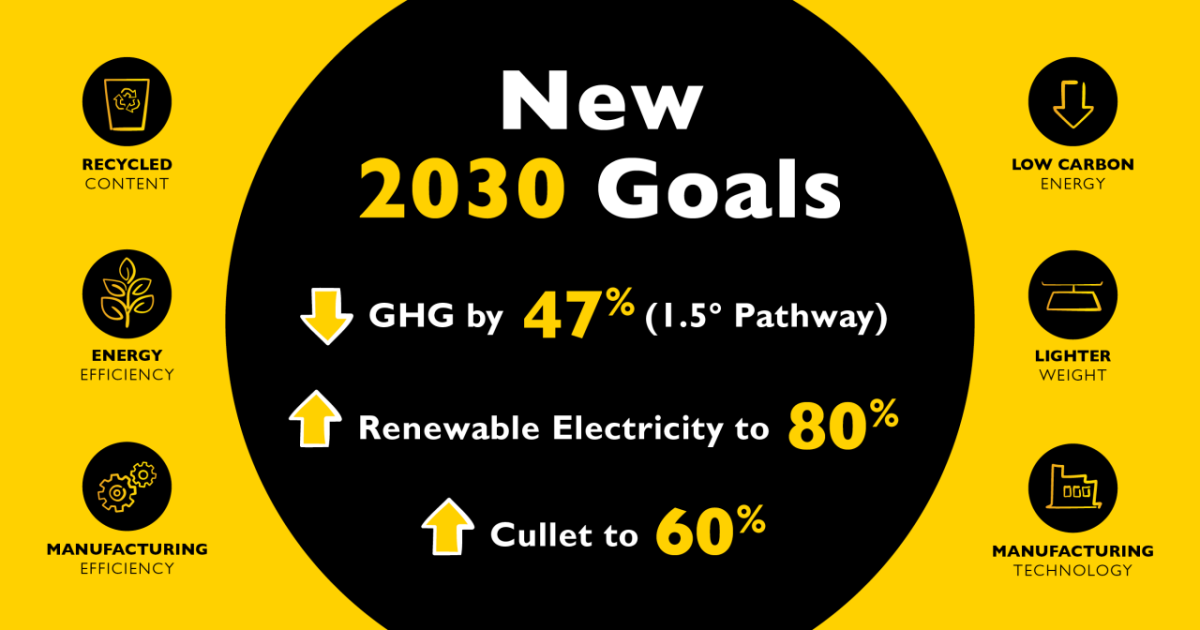

- 47% reduction in GHG emissions

- 80% use of renewable electricity

- 60% use of cullet (recycled glass) on average

These elevated goals not only put O-I on par with our competitors’ stated goals but also align with a 1.5-degree pathway.

Achieving Our Goals

Our updated goals represent a significant increase from our previous targets. Specifically, we are raising our GHG emissions reduction goal from 25% to 47%, our renewable electricity goal from 40% to 80%, and our average cullet usage goal from 50% to 60%.

To achieve these ambitious targets, we’ll leverage several key strategies:

- Renewable Electricity: A substantial portion of our GHG reduction will come from increasing our use of renewable electricity. We primarily purchase Renewable Electricity Certificates (RECs) to green our electricity supply, and we are also working on several potential solar projects.

- Recycled Content: Increasing our cullet use will play a crucial role in reducing GHG emissions. We will continue to foster recycling ecosystems, particularly where infrastructure is weak or non-existent, like in parts of our American footprint.

- Energy Management: We’ve created an energy strike team to find and destroy energy waste across our network. This highly talented cross-functional strike team is already engaged with our facilities to support them in reducing energy consumption and improving energy efficiency, contributing to our GHG reduction goal.

- Technology Improvements: We will continue to implement advanced technologies such as GOAT furnaces, hybrid electric furnaces, and the DOE project in Ohio, USA. These innovations will help us achieve our sustainability targets.

Aligning with the Paris Agreement

The elevated sustainability goals reflect O-I’s decisive action to better position the company as a leader in sustainable glass manufacturing.

“The 47% GHG reduction aligns O-I with a 1.5-degree pathway,” says O-I Sustainability Director Sonya Pump. “This aligns O-I with the target of the 2015 Paris Agreement to ‘limit the temperature increase to 1.5 degrees Celsius above pre-industrial levels.’ The idea is that keeping the temperature increase below 1.5 degrees should minimize extreme global warming effects.”

Increasing our cullet usage to 60% supports the circular economy by promoting the reuse of materials. The benefits of increased recycled content include:

- Energy Savings: Recycled glass melts at a lower temperature than raw materials, reducing the energy required in the manufacturing process and consequently lowering GHG emissions.

- Reduced Raw Material Usage: Using more recycled glass decreases the need for raw materials like sand, soda ash, and limestone, reducing GHG emissions related to using batch materials while also conserving natural resources and reducing the environmental impact of mining and transportation.

- Lower Carbon Footprint: Using recycled glass lowers the overall carbon footprint of glass production, as energy savings and reduced use of raw materials translate directly into fewer carbon emissions.

- Waste Reduction: Incorporating recycled glass into our manufacturing process helps divert glass waste from landfills, promoting a circular economy.

- Operational Efficiency: Using recycled glass can enhance operational efficiency by reducing wear and tear on furnaces and other equipment.

This alignment ensures that we remain competitive and continue to lead the industry in sustainability.

Positive Impact on Our Customers

Our updated goals will also positively impact our customers. By aligning our ambitions with those of our customers, we demonstrate our commitment to supporting their sustainability objectives.

“O-I is already leading the glass industry in delivering reductions of GHG emissions. Now, our more ambitious GHG, cullet and renewable electricity goals send a strong signal that we have no intention of slowing down,” says Pump.

Glass is 100% recyclable and endlessly recyclable. It does not cause end-of-life waste issues. Time and time again, glass proves it is the ideal packaging material to support a circular economy and the health of Earth’s people. As a long-time leader in glass packaging, we see it as our responsibility to innovate our manufacturing process to support this material’s circularity. Our ability to outpace and accomplish our previous goals and establish these updated goals is a testament to our mindset and sustainability vision.