Predictive Maintenance Offers Promise in Asset Management

When it comes to asset management, water utilities tend to weight their efforts toward preventive maintenance

Water utilities the world over faced with challenges, including of increasing demand, falling revenues and climate change. While building new assets remains part of the solution, enhancing the performance of existing assets is more important than ever before.

Download the full 2019 Water Report

The growing focus on asset management as a route to providing a high-quality service for utilities' customers – and meeting quality and environmental regulatory targets – has been driven to a large extent by the falling cost of and increased access to smart sensors and data analytics tools. The rate of change is accelerating as artificial intelligence (AI) and machine learning software similarly becomes less expensive and more widely available.

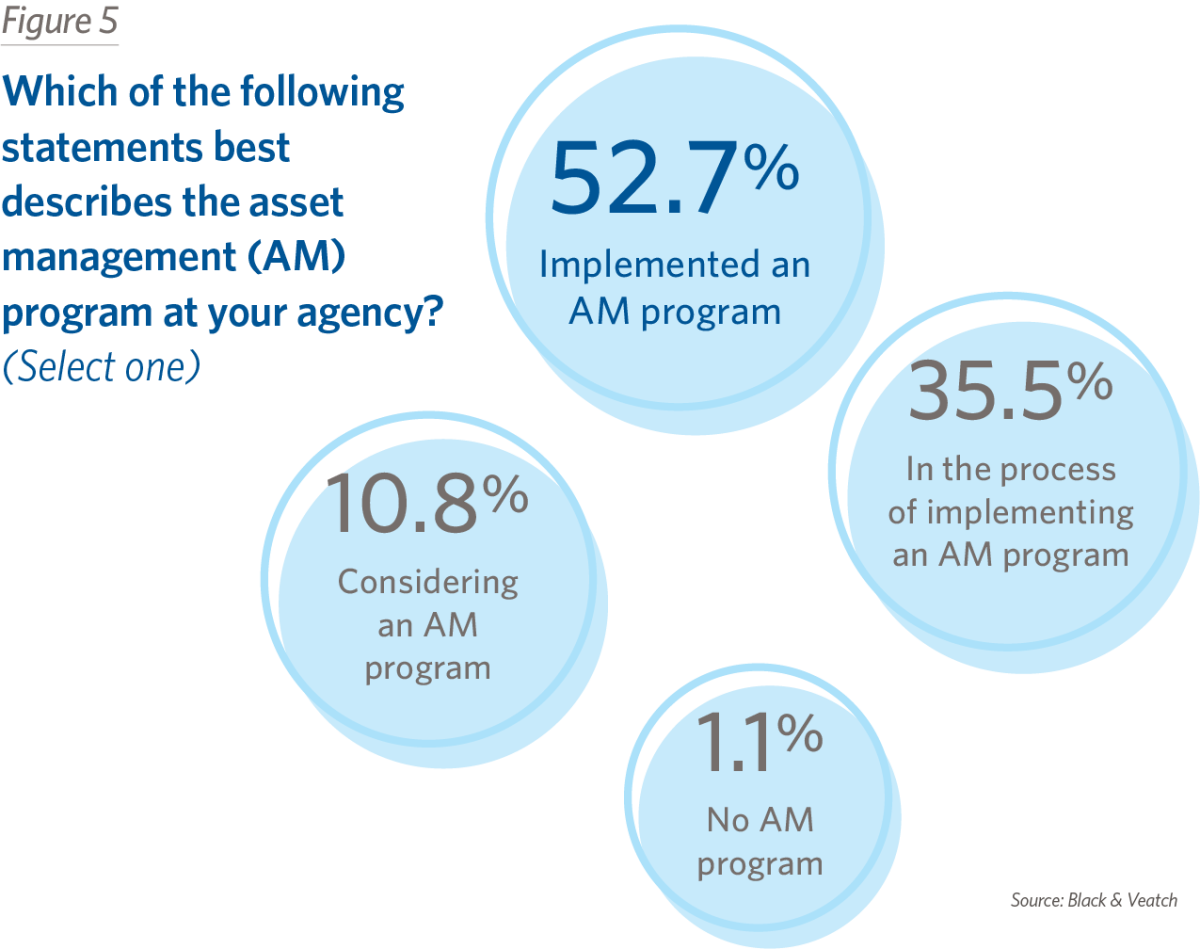

Spurred by these drivers, adoption is growing. According to Black & Veatch's 2019 Strategic Directions: Water Report survey, which polls North American water utilities, 88 percent of respondents either have implemented or are in the process of implementing an asset management program.

However, technology alone, however, is insufficient. The most successful smart asset management and maintenance programs blend human and technological excellence. Dynamic maintenance needs to be grounded in the deep institutional knowledge of an asset base that can only come from the people who design, build and operate it.

The Rise of Machines

AI and machine learning technologies allow water utilities to move beyond the descriptive analytics many currently use to understand past incidents and trends – and shift to predictive analytics, which establish what is likely to happen, and prescriptive analytics, which suggest actions based on predictions.

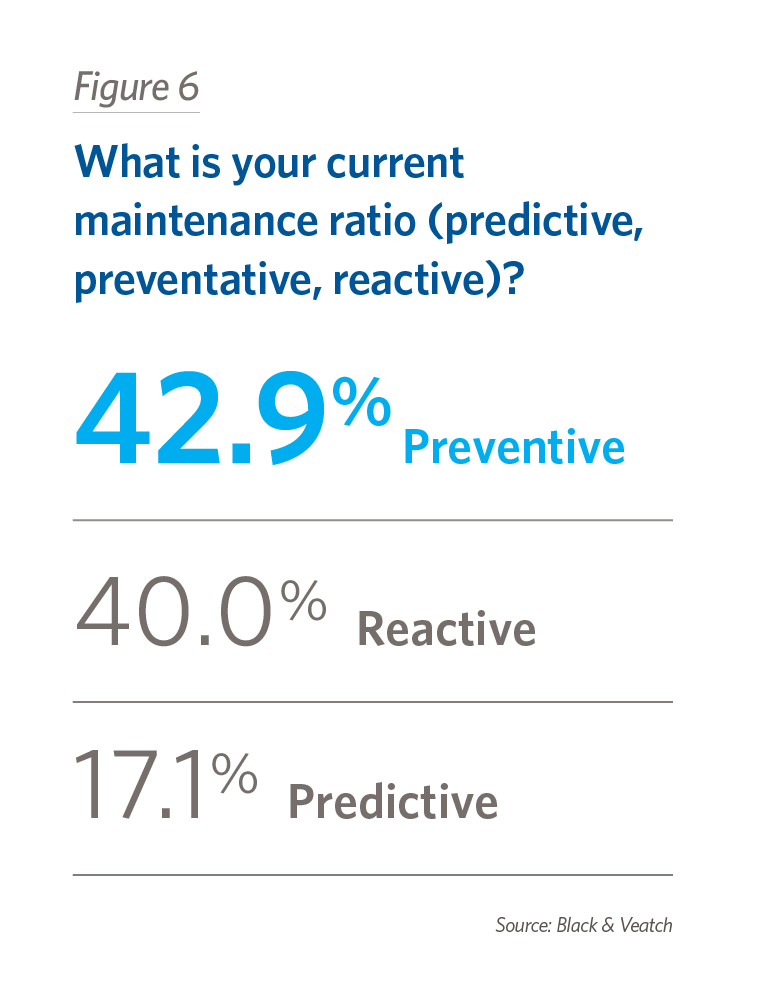

When it comes to understanding how utilities approach asset maintenance, survey data shows that, on average, they tend to weight their efforts more heavily toward preventive maintenance, which accounts for 43 percent of respondents, followed by reactive (40 percent) and predictive (17 percent). These results show an opportunity for utilities to eventually shift from reactive strategies and toward a more predictive approach.

The Internet of Things (IoT) will be an important enabler for these approaches. The IoT is made up of connected devices, from simple sensors to smartphones. The internet's ubiquity and the availability of cheap sensors make possible ever-increasing, cost-efficient gathering of condition and performance data.

Sensors connected via the internet for the purposes of analytics make the visibility of performance cheaper. This gives the flexibility to extend lower-cost performance monitoring into areas where the level of criticality traditionally would not justify more expensive control and protection systems, but where the asset failure would not be without cost implications.

These technological advances are helping facilitate new approaches to how assets are managed and operated:

- Dynamic Preventive Maintenance (DPM), which prevents failures before they occur by using intelligent predictions and dynamic maintenance planning.

- Prognostic Maintenance Interventions (PMI), which use machine learning, pattern recognition and advanced analytics to optimize, manage and deliver interventions.

Data Comes at a Price

The volume of data these technologies make accessible to a water utility is potentially overwhelming. In addition, there is a cost to capturing, storing and accessing each data point. So when developing DPM and PMI strategies, it is vital that utilities define the assets and related data that best support their goals – and focus only on them.

Failure to achieve this has resulted in data gathering initiatives that cost more than the savings they were expected to yield. Capturing and storing data and – most importantly – maintaining accurate, up-to-date information can be costly.

Like physical assets, asset data has a life cycle. About 20 percent of the cost of gathering asset data comes in the capital phase of the asset's life cycle. The remaining four-fifths of data costs are generated during the operations and maintenance (O&M) phase. This is due in part to the length of the capital phase compared to the O&M phase, but mostly because O&M data is live, evolving and in need of ongoing monitoring, storage and updating.

Understanding the costs associated with the different phases of the asset data life cycle – and planning data acquisition accordingly – is the cornerstone of dynamic preventive maintenance. Harvesting unneeded data combined with the risk of using bad data comes, literally, at a price.

After the most significant assets and associated data have been identified, their criticality can be understood. This means focusing on what an asset or process is intended to do and identifying factors that stop it from performing as required. This information is used to inform measures to mitigate the factors degrading asset performance, creating a condition or output-based maintenance regime at the optimum balance between cost, risk and performance.

That root cause analysis and failure mitigation will allow water utilities to better understanding planned and unplanned costs across comparable process and, if they differ, understand why. This will provide vital insights into the true cost-to-serve.

Toward Maintenance 4.0

DPM and PMI programs mark a significant step toward Maintenance 4.0 – the fourth industrial revolution and the shift toward cyber-physical systems. Water utilities need to embrace this change, knowing that technology is only part of the solution.

To deliver the smartest possible maintenance solutions, O&M teams will need to trust in AI-driven programs. For this to work, the AI platform needs to be founded on the deep institutional knowledge of water utility design, construction and O&M experts.