Similarities, Differences and Synergies of Life Cycle Assessment and Greenhouse Gas Inventory Methods

WSP USA’s Julie Sinistore and Praneet Arshi examine each method of baselining a company’s environmental impacts and how to extract the most value from both.

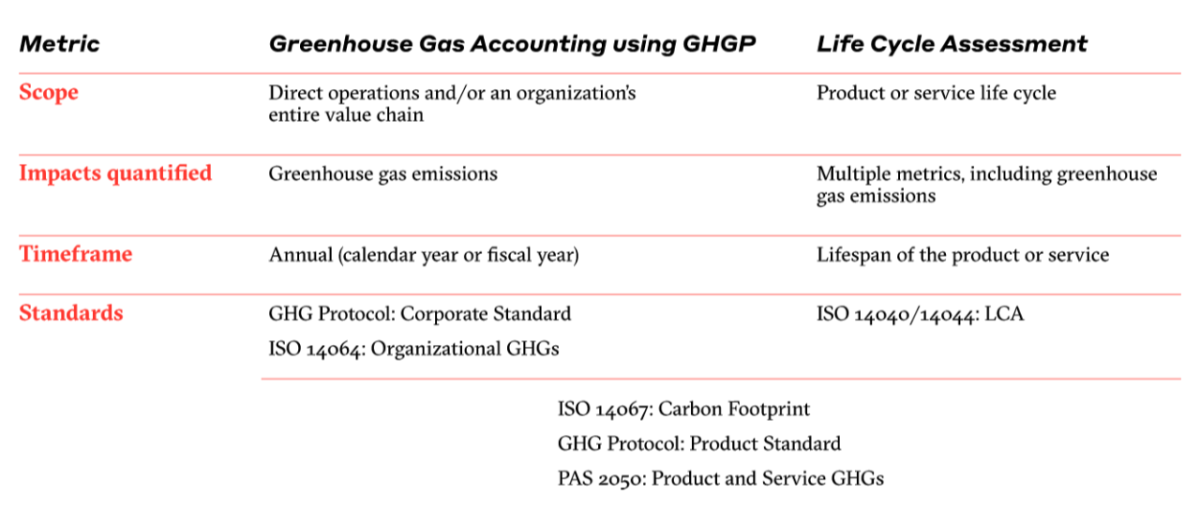

Life cycle assessment (LCA) and greenhouse gas (GHG) inventories are two key measurement tools being used to track an organization’s environmental impact.

Is one more effective than the other? The answer usually depends upon the situation and the objectives for the organization. And sometimes, the answer is “both.”

WSP USA partners with organizations aiming to be Future Ready®, helping them understand the differences and similarities between LCA and GHG inventory methods and data, and identifying whether it is beneficial to use each methodology separately or together to gain the most value and guide sustainability strategy.

What are LCAs and GHG Inventories?

LCA is a tool used to quantify the environmental impacts from the raw materials, production, transportation, use and end of life of a product or service.

LCAs are often conducted to understand the total environmental impacts of a particular product or service and the drivers of those impacts. The goal is usually to reduce the environmental impacts such as GHG emissions, energy, air quality, water consumption and water quality indicators of those products and services, and to communicate to clients and customers about these impacts and how they compare to alternatives.

On the other hand, an organization’s GHG inventory is a summation of all the greenhouse gas emissions from an organization across its value chain. GHG inventories are typically conducted to support company-wide reporting, set GHG emissions reductions targets for entire organizations and track progress towards meeting targets. It is an excellent way to identify and understand the largest sources of GHG emissions within an organization.

GHG emissions are typically categorized into three scopes:

- Scope 1 – Direct (fossil fuel combustion in vehicles, generation of heat and power

- Scope 2 – Indirect (purchased electricity)

- Scope 3 – Emissions from the value chain split into 15 categories (such as upstream purchasing of goods, downstream use of sold goods, employee commuting and business travel).

Insights from Performing an LCA

There are several reasons why an organization might conduct an LCA.

It could be the need to drive internal innovation towards environmental impact reduction of products and services. Perhaps the organization is required to satisfy an external policy requirement or client request. Maybe there is a demand to substantiate external marketing claims about the singular or comparative sustainability of a product or service. Or it may be a time for re-evaluation of a product’s environmental impacts in order to pivot toward more sustainable designs. Also, LCAs often provide environmental impacts beyond just GHG emissions that provide insights into the holistic environmental impacts of the product or service.

Extracting the most value from an LCA means engaging partners across the organization from design to marketing to drive innovation and communicate results strategically.

Often, LCA results are highlighted in annual sustainability reports and can help track progress towards GHG emissions reductions targets over time, particularly as it relates to purchased goods and services, use of sold products and other Scope 3 categories. A type of LCA, called an environmental product declaration (EPD), is a precise format for communication of an LCA based on a product category rule for all products that fall into that category.

EPDs are valuable standardized methods of reporting LCA results to customers and serve as useful marketing tools. They also inform other LCAs and GHG inventories.

WSP completed an ISO-conformant comparative LCA for Perfect Day, a manufacturer of animal-free dairy protein. The analysis compared Perfect Day’s non-animal whey protein and the total protein in bovine milk to demonstrate that Perfect Day’s whey substantially reduces GHG emissions, energy and water consumption.

Perfect Day can now use these results to support its communications about the enhanced environmental attributes of its whey with confidence because the study was critically reviewed by a panel of three independent experts and verified to be in accordance with ISO-standards 14040 and 14044. This is considered best practice to support environmental claims.

Now, if a food manufacturer uses Perfect Day’s whey to replace other ingredients, the results of the LCA can inform its own LCAs and Scope 3 GHG inventory and calculate potential reductions in GHG emissions and other environmental impacts.

Furthermore, if Perfect Day decided to conduct its own GHG inventory to better understand the GHG emissions footprint of the organization and identify additional opportunities to extend its environmental impact, it could use the results of the LCA to inform several Scope 3 categories.

Insights from Performing a GHG Inventory

Organizations calculate GHG inventories for many reasons. They provide valuable business information that can be used to create strategies for GHG emissions reduction. GHG inventories also increase organizational environmental transparency through reporting, and they are useful for setting and tracking progress towards achieving GHG emissions reductions goals over time.

Clients, investors and other stakeholders may request the results of a GHG inventory be included in standard reporting and may evaluate the organization based on its ability to meet GHG emissions reduction targets. WSP calculates its own GHG inventory and has helped numerous organizations calculate GHG inventories, set targets for reductions, create roadmaps for reduction and track progress toward reaching reduction goals.

GHG inventories are much more suited to large-scale analysis of entire organizations than LCA. That is not to say that LCA cannot be applied to an organization, but it can take more time and require more data to accomplish this evaluation with LCA than with GHG inventory methods and data.

WSP collaborated with The Children’s Place, a specialty retailer of children’s apparel, as a professional services provider to develop a GHG inventory for the company’s climate disclosures. In this role, WSP’s Sustainability, Energy and Climate Change team calculated the company’s first water inventory and collected and analyzed GHG emissions data to identify areas where there were opportunities to reduce environmental impact.

The data was collected and used to calculate the annual reporting data concerning energy and water usage and GHG emissions, which was reported in The Children’s Place’s 2020 Environment, Social and Governance Report. Using the data, the retailer set climate and energy goals that they aim to achieve by 2030, including a 30 percent reduction of Scope 1 and Scope 2 market-based GHG emissions across its global operations, and a 30 percent reduction of Scope 3 GHG emissions from purchased goods and product transport.

For certain Scope 3 GHG accounting categories, spend data are commonly used to calculate the emissions. The spend data assign a GHG emissions intensity per dollar spent, which is applied to the amount of money an organization spends in each Scope 3 category. This is very useful to get a sense of the most relevant categories driving an organization’s GHG emissions.

It becomes more difficult, however, to reduce GHG emissions in these categories without more product, service and category-specific data. Industry-wide GHG emissions data on product types from published LCAs or EPDs are increasingly available and using such data can improve the specificity of the GHG inventory and highlight more actionable targets than spend data.

If an organization specializes in manufacturing particular products, then product-specific LCAs could further improve the accuracy of the GHG inventory and highlight particular parts of the supply chain to focus on for GHG emissions reduction.

There is a product carbon footprint standard from the GHG Protocol, but this covers only GHG emissions and no other environmental impacts such as water and air quality, water use, consumption and scarcity, energy or other categories that can be included in an LCA. Therefore, as a quantification method, corporate carbon accounting cannot be used to enumerate environmental impacts other than GHG emissions from the production, transportation, use and end of life of a product.

Blending Both Methods

There is some confusion in the sustainability space between LCAs and GHG inventories. For example, neither method produces better or more accurate results than the other. The accuracy of either method depends on the accuracy of the input data.

They can, however, be used in tandem to support the overall environmental objectives of an organization.

LCAs can make the Scope 3 data input for a GHG inventory more precise and support the calculation of, and deeper dive into, GHG inventory Scope 3 areas, including Category 1 (purchased goods and services), Category 10 (processing of sold products), Categories 4 and 9 (upstream and downstream transportation and distribution), Category 11 (use of sold products) or Category 12 (end-of-life treatment of sold products).

WSP is conducting both product LCAs and GHG inventories for many organizations and uses the results of product LCAs and EPDs to calculate more precise and actionable Scope 3 GHG emissions. The key is understanding which results can be used to inform the categories in Scope 3 GHG inventories.

A recently published white paper co-authored by Microsoft and WSP, LCA Guidelines for Cloud Providers, explores the importance of understanding the life cycle of GHG emissions, energy, water and other environmental impacts of technology, from servers to full datacenters