Testing the Vehicle of Tomorrow at Keysight’s Automotive Tech Day, Novi

By Emily Yan Product Marketing Manager

With the growing demand for autonomous functions, enhanced connectivity, and smartphone-like in-vehicle experience, the automotive industry is undergoing a seismic shift toward software-defined vehicles (SDVs) and electric vehicles (EVs). To stay ahead, original equipment manufacturers (OEMs) need new test solutions to speed up the development cycles while ensuring compliance with ever-changing industry standards, including safety, interoperability, conformance, and security.

To explore the opportunities and challenges of this shift, Keysight’s annual Automotive Tech Day at the Novi Automotive Customer Center (ACC) in the U.S. recently brought together over 150 R&D professionals to share how the latest testing and emulation technologies can fast-track SDV and EV innovations. In addition to hands-on demonstrations from Keysight experts, attendees heard practical insights from Keysight solutions partners, including Binder, Block Harbor, ETAS, and Konrad Technologies, during insightful technical presentations.

Future-proofing EV charging test with emulation

Last year, new electric car (EV) registrations in the United States reached 1.4 million, a 40% increase from 2022. The Department of Energy (DoE) has reported that EV charging ports also doubled in the same period.

For EV growth to keep up the momentum, safety, interoperability, and conformance of new EV charging products are paramount to accelerate new products’ time-to-market and meet consumers’ demand.

However, today’s EV charging ecosystem faces a significant test challenge: the lack of harmonized standards. The market is awash with new manufacturers and varying standards set by different regions. How can R&D teams navigate this intricate regulatory landscape and deliver high-quality products without compromising time-to-market goals?

Advanced emulation of real-world charging stations and electric vehicles in the lab might hold the key.

During the Automotive Tech Day, Keysight’s tech expert, Paul Centkowski, demonstrated our Charging Discovery System (CDS) and its three main use cases:

- Man-in-the-middle test,

- EV test,

- EVSE (EV supply equipment) test.

In Paul’s demo, the CDS system automates the testing of all AC and DC charging interfaces and performs all necessary conformance and interoperability tests according to multiple global standards, including CCS, CHAdeMO, and GB/T.

Additionally, the CDS can be combined with Keysight's advanced regenerative power systems. This bidirectional power supply is scalable and versatile for low-power DC testing, such as onboard chargers. Its regenerative capability returns 90% of its power to the grid, saving recurrent cooling and overall testing costs.

For high-power scenarios, check out our SL1800A Scienlab Regenerative DC Emulator if you look to achieve high-power DC charging test up to 300 kW in a small footprint. Additionally, the SL1200A series is designed to handle all your 3-phase AC test needs up to 1200 VAC, from 30 to 630 kVA without the need for a transformer.

Taking vehicle connectivity to new heights

Functionality advancements in SDVs require high-bandwidth and low-latency in-vehicle networking (IVN) technologies. More automakers have adopted automotive Ethernet due to multiple advantages over traditional technologies like LIN and CAN, including higher bandwidth, enhanced data transmission, scalability, and reduced latency. Comprehensive Ethernet testing becomes essential to ensure reliable operations across electronic control units (ECUs). However, testing engineers often find it challenging to ensure rigorous compliance verification and create real-life workload simulations in the lab.

During the "In-Vehicle Networking Communication and Security" session, Keysight’s solution engineer, Cris Fernandes, highlighted several key testing considerations for automotive Ethernet.

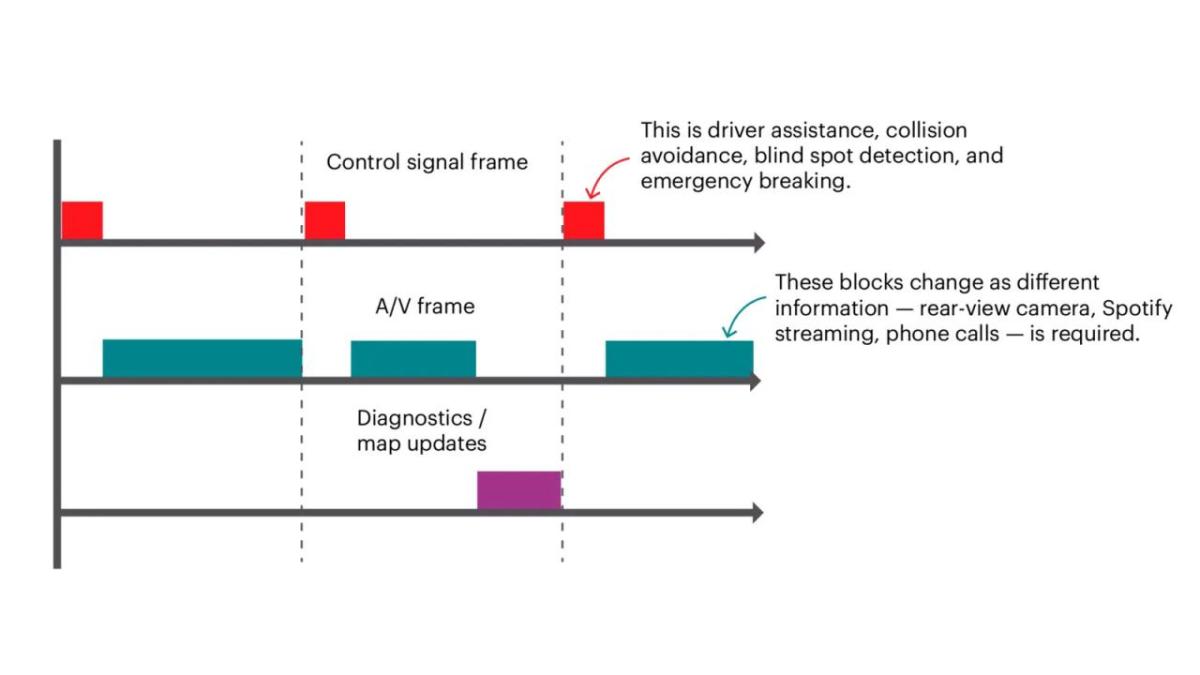

One key aspect is Time-Sensitive Networking (TSN), a collection of IEEE standards that enable multiple interfaces to be replaced with one standard transmitted over an unshielded twisted pair (100M/1000M BASE-T1). Figure 2 shows a simplified version of what might occur in a single port: ADAS (Advanced Driver Assistance Systems), infotainment, and regular updates. In a real system, one port might handle 150 to 200 data streams, each with distinct priorities, emergency levels, and application data. TSN testing examines the entire network narrative, making precise measurements of packet loss, latency, jitter, and delay.

Keysight’s automotive Ethernet solutions provide end-to-end functional and standard-compliance conformance testing for automotive Ethernet chipsets and devices. Recently, we assisted a semiconductor manufacturer in implementing a new 1 Gbps automotive Ethernet test with TSN.

Using Keysight’s Infiniium MXR-Series real-time oscilloscopes, automotive Ethernet compliance solutions, and IxNetwork L2–3 network infrastructure performance testing, the customer quickly set up and tested automotive Ethernet designs while simulating realistic user applications and scenarios in the lab.

Confronting growing automotive cyber threats with fuzz testing

The transformation from isolated systems to software-defined vehicle vehicles (SDVs) opens up various new cyber-attack paths, ranging from cryptographic attacks to over-the-air (OTA) protocol exploits. In 2023 alone, there were 295 cybersecurity incidents in the automotive space.

In SDVs, functionalities once distributed across multiple ECUs are now consolidated onto fewer high-performance computers (HPCs). These HPCs run various applications, including ADAS, infotainment, and communications. As they interact with external systems, they become more vulnerable to erroneous input from external sources, unpatched software, and sluggish response protocols in newly connected systems.

To combat these threats, the industry has adopted several cybersecurity standards and regulations:

- ISO/SAE 21434: 2021 Road Vehicles—Cybersecurity Engineering

- Automotive SPICE for Cybersecurity

- UN Regulation No. 155 – Cybersecurity and Cybersecurity Management System

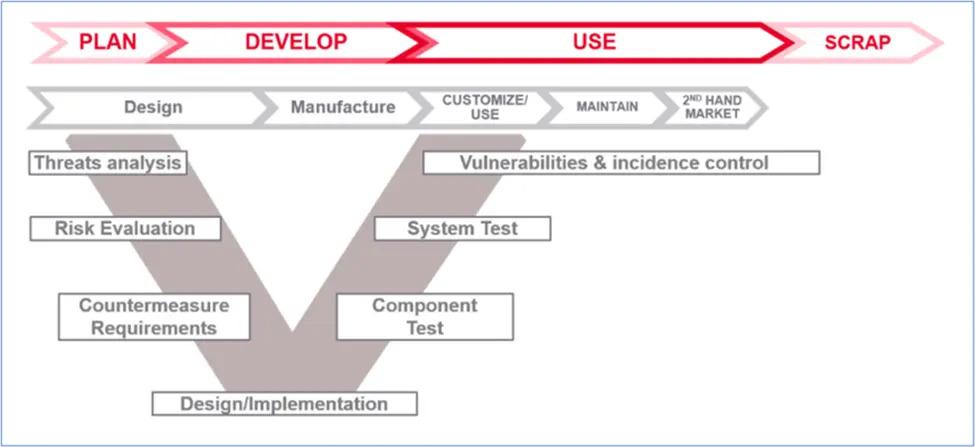

Cybersecurity is integral to the automotive V-model development process, covering threat analysis, risk evaluation, countermeasure requirements, and various testing activities such as functional testing, vulnerability scanning, fuzz testing, and penetration testing.

During the Automotive Tech Day, ETAS cybersecurity experts introduced the importance of Controller Area Network (CAN) fuzz testing. Recommended by ISO 21434, fuzz testing involves injecting invalid, malformed, or unexpected inputs to the device under test (DUT) to identify hidden software bugs or vulnerabilities that can lead to insecure behaviors, transition into undefined states, or system crashes.

Keysight's automotive cybersecurity test platform provides automated testing across all layers of the Open Systems Interconnection (OSI) stack for in-vehicle interfaces. By embedding ETAS’ ESCRYPT CycurFUZZ, Keysight has enabled rapid fuzz testing via CAN interfaces. Test engineers can automatically scan the DUT’s automotive CAN bus to mitigate cybersecurity risks associated with it and ensure compliance with regulations such as UN R-155.

Join Keysight Automotive Cybersecurity Boot Camp

Conclusion

Electrification, greater autonomy, and increased connectivity are revolutionizing automotive design today. As these trends advance, automotive manufacturers are looking to test solutions to ensure vehicle safety and accelerate time-to-market. Keysight has a unique vantage point for these innovations as our expertise spans the entire development cycle.

To learn how we can help you drive greater performance and reliability into the future of mobility, request a custom solution demo, inquire about automotive testing training, or visit our ACC in a city near you.