Texas A&M Students Create Building Envelope Designs from GM Manufacturing Scrap

Texas A&M Students Create Building Envelope Designs from GM Manufacturing Scrap

General Motors thinks of waste as a resource out of place. To help make the zero-waste mindset more mainstream, the company engages others in its mission, including students. Most recently it was Texas A&M University’s College of Architecture helping reimagine waste materials to keep them in use.

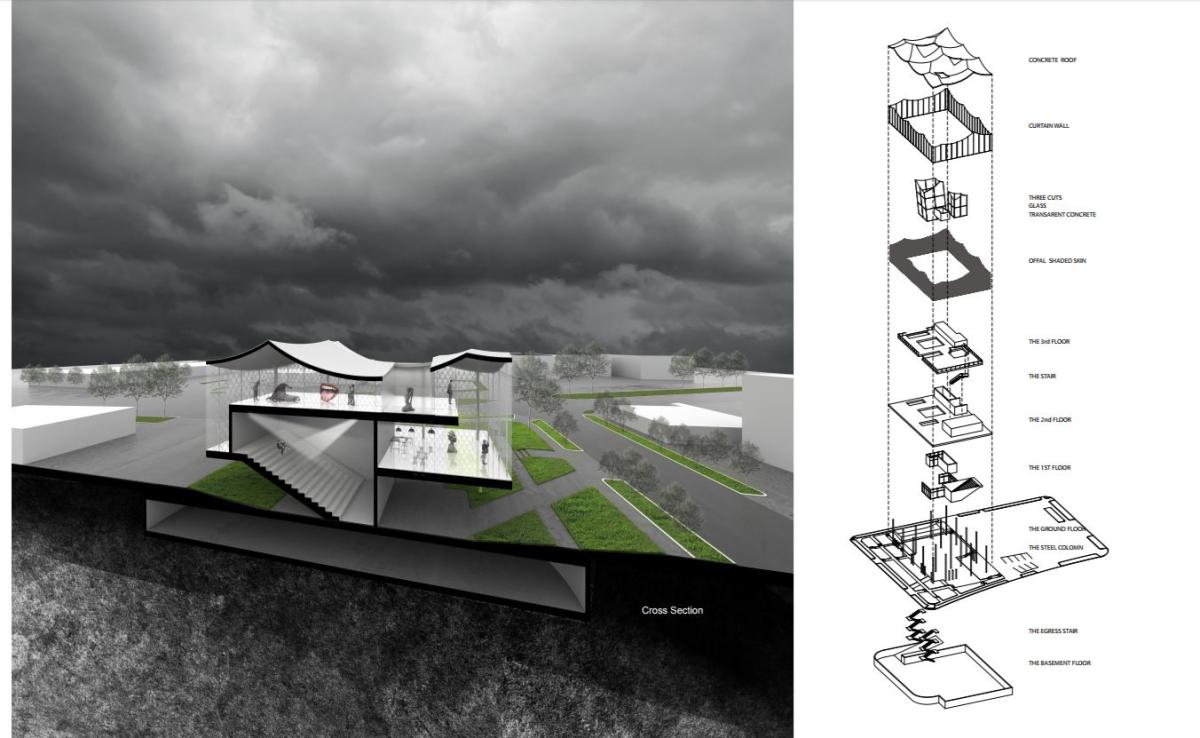

The students’ assignment was to design the Houston Museum of Waste, an imaginary 27,000-square-foot museum. As in many projects, there was a challenge. They had to incorporate offal – a galvanized piece of thin sheet metal left over when stamping out car parts – within the building’s physical separation of its interior and exterior. This variable encouraged students to provide a novel solution to design a building envelope using byproducts from the manufacturing industry.

The jury committee included experts and professionals from GM; U.S. Business Council for Sustainable Development; Zahner; Lake|Flato Architects; and Corgan Associates. The jury credited the winner, Yingzhe Duan, for her use of offal in a functional, practical and replicable way. Yingzhe’s museum proposal delivered an airy, translucent appearance thanks to its simple, open floor plan, glass walls and an interior shading system made from offal sheet metal.

Dr. Ahmed K. Ali, the director of the resource-based Design Research Lab and an assistant professor of architecture at Texas A&M University, organized the initiative.

“Typically architects will design first and then figure out which material will fit,” said Dr. Ali. “Our students thought about the process in a new way. I call this approach ‘synergistic means-oriented design.’ They looked at a challenge – in this case, manufacturing waste – and identified an application to use it.”

GM’s Global Waste Reduction Manager, John Bradburn, served on the judging panel.

“To advance the circular economy, we need to collaborate with other industries and individuals, and think bigger and broader about secondary uses for the nation’s waste streams,” said Bradburn. “For us, it means considering homes for our byproducts beyond the manufacturing sector and encouraging others to apply the same mindset.”

The project will continue through a three-year grant engaging multidisciplinary teams of faculty and graduate students across four Texas A&M departments, including architecture, construction science, engineering and mathematics. Together the teams will tackle real-world projects relating to the circular economy revolution. GM will continue to serve as a partner and advisor.

Although GM generates significant revenue from recycling various materials, largely scrap metal, keeping the material in use is the best management method. Earlier this year, GM donated scrap sound-deadening material found in Chevrolet engines for use as insulation in a jobs development and training facility in Flint, Michigan, instead of sending it to a traditional recycler.