Water May Be Cheap; Using It Isn’t

Watching water move down a river can lull us into thinking it’s as free as it is free-flowing. But this resource, which we share with our communities, isn’t free. In recent years, Domtar has taken a closer look at the costs of using water in making pulp and paper. And thanks to a variety of process improvements, we are seeing greater water efficiency and lower costs.

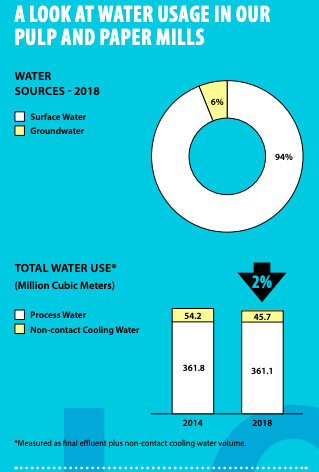

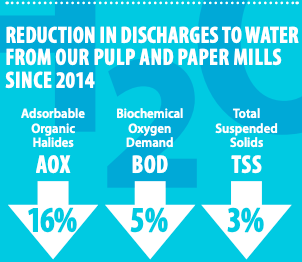

We are intentional about our water efficiency, and we return nearly 90 percent of it to its source. In some cases, the water we return is cleaner and clearer than it was originally.

“While Domtar’s mills operate in areas with ample water supplies – and in most locations, we pay little to no fees to withdraw water – we don’t want to fall into the trap of taking this resource for granted,” said Brian Kozlowski, senior manager for sustainability performance optimization. “We understand water is a shared resource that we borrow from nature.”

The cost to Domtar to pump, filter, demineralize, treat, heat, reuse and clean the water before returning it to the environment is anything but free. Water costs are complex, comprising long-term, short-term, fixed and variable costs. And they matter, both to the bottom line and to the communities where we operate.

Our 13 pulp and paper mills are located in watersheds with unique geographies and climates, from the southeastern United States to Canada. The land that surrounds our facilities may be forested, agricultural or urban, with a range of upstream and downstream water users, from manufacturers and farmers to cities and residential areas.

All of these factors affect the quantity, quality and availability of water. Our mills must be prepared to treat water in changing conditions, including:

- Varying water temperatures and flows from season to season

- Weather-related events, such as flooding, storm surges and drought

- Turbidity resulting from runoff from the landscape

- Algal blooms from upstream activities that enrich surface water with nutrients

“Developing our full-cost-of-water model has been a broad effort supported by colleagues in sustainability, energy and finance, in close partnership with our local manufacturing leaders,” said Kozlowski. Domtar completed its model to quantify the full cost of water use for our pulp and paper mills and began adopting it in our mill system in 2018.

WATER EFFICIENCY REDUCES COSTS AND INFORMS OUR INVESTMENTS

Evaluating water efficiency and costs requires several years of data. For example, some water costs, such as obtaining a wastewater discharge permit, occur once every few years, rather than annually. Water licenses and permits, as well as water testing and labor associated with water access, use and treatment, are generally fixed costs that don’t change with water use.

Other costs are variable or semi-variable, areas in which water conservation efforts can offer opportunities for savings. Energy and chemical use are two of the most significant variable costs and are directly linked to the amount of water used.

Understanding the full cost of water is also becoming an increasingly important tool for our mills when planning – and justifying – capital investments. As an example, the Plymouth Mill’s cooling tower heat/exchanger project was the first application of Domtar's cost-of-water model, which ultimately influenced the nature and components of the project.

As we improve our water efficiency, we can lower our costs in several areas. And as we expand the use of our cost-of-water model, our understanding of water costs help us make more sustainable investment decisions.